- (905) 405 0000

- pm@fireville.com

- Unit 28 20 Wertheim Crt Richmond Hill, On

When it comes to fire safety in buildings, prevention is always better than cure. One of the most effective ways to safeguard structures and their occupants from the devastating effects of fire is through the use of intumescent coatings. At Fireville™, we specialize in providing cutting-edge fire protection solutions, and intumescent coatings are one of our most trusted tools in the fight against fire. In this blog post, we’ll explore what intumescent coatings are, how they work, and why they’re essential for modern fireproofing.

When it comes to fire safety in buildings, prevention is always better than cure. One of the most effective ways to safeguard structures and their occupants from the devastating effects of fire is through the use of intumescent coatings. At Fireville™, we specialize in providing cutting-edge fire protection solutions, and intumescent coatings are one of our most trusted tools in the fight against fire. In this blog post, we’ll explore what intumescent coatings are, how they work, and why they’re essential for modern fireproofing.

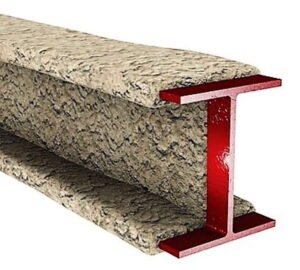

Intumescent coatings are specialized fire-resistant materials applied to structural elements like steel, wood, and concrete. Unlike traditional fireproofing methods, which often involve bulky materials like concrete or gypsum, intumescent coatings are thin, lightweight, and aesthetically pleasing. They are typically applied as paint or spray, making them ideal for both new constructions and retrofitting existing buildings.

The word “intumescent” comes from the Latin intumescere, meaning “to swell up.” This is exactly what these coatings do when exposed to high temperatures. When a fire breaks out, the coating expands to form a thick, insulating char layer that protects the underlying material from heat and flames.

Intumescent coatings are a marvel of fire science. They consist of three key components:

Acid Source: Typically ammonium polyphosphate, which reacts under heat to form a protective char.

Carbonific Compound: Often pentaerythritol, which provides the carbon needed to create the char.

Blowing Agent: Such as melamine, which releases gases to expand the char layer.

When exposed to fire, the coating undergoes a chemical reaction. The heat causes the blowing agent to release gases, which expand the coating into a foam-like char. This char acts as an insulating barrier, slowing down the transfer of heat to the structural element and maintaining its integrity for a specified period—typically 30 minutes to 2 hours or more, depending on the product and application.

Structural Integrity in Fires: Steel, a common building material, loses its strength at temperatures above 550°C (1,022°F). Intumescent coatings protect steel beams and columns, ensuring they remain stable and functional during a fire, giving occupants more time to evacuate and firefighters more time to respond.

Aesthetic Appeal: Unlike traditional fireproofing methods, intumescent coatings are thin and can be painted over to match the building’s design. This makes them ideal for visible structural elements where aesthetics matter.

Lightweight and Versatile: Intumescent coatings add minimal weight to structures, making them suitable for high-rise buildings and other applications where weight is a concern. They can also be applied to complex shapes and hard-to-reach areas.

Compliance with Fire Safety Regulations: Building codes and fire safety standards, such as those set by the NFPA (National Fire Protection Association) and local authorities, often require fireproofing measures. Intumescent coatings help builders and property owners meet these requirements efficiently.

Cost-Effective Fire Protection: By preventing structural damage during a fire, intumescent coatings can save property owners significant repair and replacement costs. They also reduce insurance premiums in many cases.

Intumescent coatings are incredibly versatile and can be used in a wide range of applications, including:

Commercial and Residential Buildings: Protecting steel beams, columns, and other structural elements.

Industrial Facilities: Safeguarding warehouses, factories, and oil refineries.

Transport Infrastructure: Fireproofing bridges, tunnels, and airports.

Heritage Buildings: Providing fire protection without compromising historical aesthetics.

Not all intumescent coatings are created equal. The right product depends on factors such as:

Fire Resistance Duration: How long the coating needs to protect the structure (e.g., 30 minutes, 60 minutes, 120 minutes).

Substrate Material: Steel, wood, and concrete each require specific formulations.

Environmental Conditions: Indoor and outdoor applications may require different coatings.

Aesthetic Requirements: Some coatings are designed to be painted over, while others are available in a range of finishes.

At [Your Fireproofing Company Name], we work closely with our clients to assess their needs and recommend the best intumescent coating solution for their project.

As building designs become more innovative and fire safety standards continue to evolve, intumescent coatings are playing an increasingly important role in modern construction. Advances in technology are leading to coatings that offer longer fire resistance, better environmental performance, and easier application.

At [Your Fireproofing Company Name], we’re committed to staying at the forefront of these developments, ensuring our clients have access to the most effective fireproofing solutions available.

Fire safety is not something to take lightly. Intumescent coatings offer a reliable, cost-effective, and aesthetically pleasing way to protect your property and the people who use it. Whether you’re constructing a new building or upgrading an existing one, intumescent coatings are a smart investment in safety and peace of mind.

Ready to learn more? Contact Fireville™ today to schedule a consultation and discover how intumescent coatings can enhance the fire safety of your project.

About Fireville™:

Fireville™ is a leading provider of fireproofing solutions, specializing in intumescent coatings, fire-resistant materials, and fire safety consulting. With years of experience and a commitment to excellence, we help our clients build safer, more resilient structures. Let us help you protect what matters most.